FIRE AND STEEL:

The steel used in KOMPACTOOLS range is produced in the most modern sinter plant. It delivers top performance in terms of durability, maximum wear resistance, high hardness, dimensional stability and high compression resistance.

SUCETOOL, your reliable powder metallurgical tool company, provide all the durability, quality and strength you need.

A tough, “long distance runner” with an optimum chemical composition

ESR electro slug remelting: a tried and tested remelting technology developed by Bohler gives the material the homogeneity it needs. A prerequisite for the best performance

ESR Manufacture improved service life due:

•Least possible inclusion content

•Lower micro and macro segregation

•Good homogeneity and higher degree of purity

•A homogeneous structure throughout the entire cross-section and bar length

•Producing larger bar dimensions at a constant carbide distribution

•Uniform correction of dimensions

•A broad range of application due to a high degree of toughness

The new K360 isodur is a further development of the 8% chromium steels and has been developed to meet the needs of customers now more than ever. High toughness and, a remarkably high compressive strength, together with good resistance make this steel a real problem solver.This steel is particularly outstanding when adhesive and abrasive wear resistance are necessary; it allows a considerable increase in performance , your productivity will increase and your costs per part will be reduced

Today Suce provides,in addition to the traditional HSS punches,of new variety of tools,Trumpf style and Thick turret style made in powder steel metallurgical.

One of them is K490.

Research shows that the K490 Microclean, thanks to its chemical composition, is the best steel in the punching market. If you compare it with other powder steels, for example M4 and PM23,you will find that it assures twice the toughness with the same wear resistance.

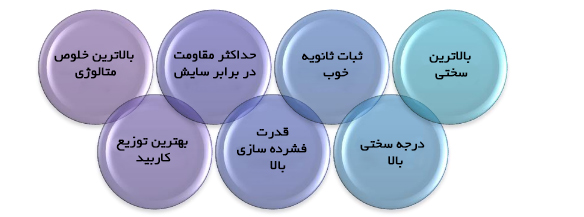

This new material is characterized by:

–A high adhesive and abrasive wear resistance

More hits between regrind operations increases tool life , wear resistance double than traditional HSS M2

–A high toughness reduces risk of breaking the punch

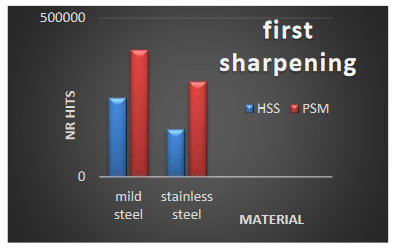

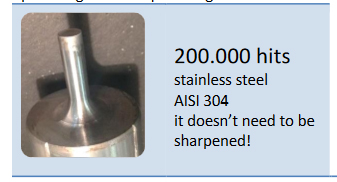

Test result

In order to ensure the best choice of steel for our tools, are carried

out periodically punching test with punching machine

Graphic shows nr of hits before first sharpening punching mild and stainless steel with HSS and PSM tool Tool tested square 6mm